Good news: Join us in celebrating this new wave

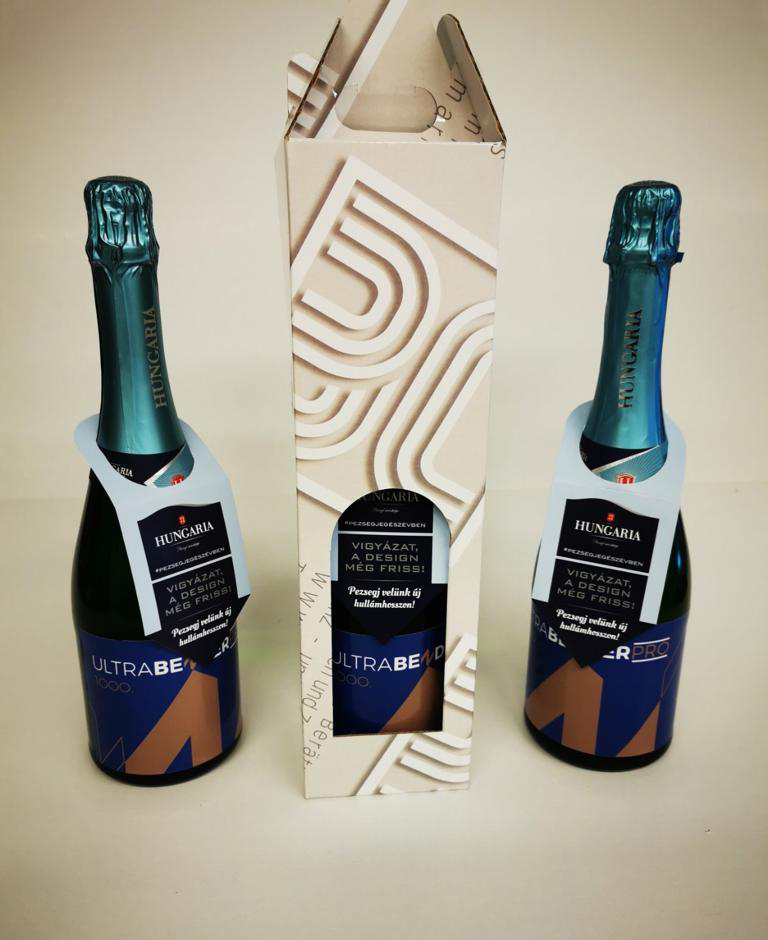

Congratulations on the successful installation of the 1000th Richly Top’s auto bending machine to the UK customer Fast Finish. This is also the second Ultrabender for Fast Finish. Thanks again to Fast Finish for its support and trust. To commemorate this historical moment, our UK agent, Nathan of EMG Diesupplies, presented the Hungarian special edition Ultrabender champagne to Fast Finish during delivery and celebrated together.

Our UK agent, Nathan of EMG Diesupplies, presented the Hungarian special edition of Ultabender champagne to Fast Finish

Fast Finish employees took photos in front of the 1000th Ultrabender

Richly Top Hungarian special edition Ultrabender champagne

"Be careful, this design is still fresh. Let's celebrate this new wave —Ultrabender"

The 1000th Ultrabender is manufactured in our Hungarian production line. Thank Richly Top overseas colleagues for their hard work and strive for Richly Top's beautiful tomorrow!

product information:

Ultrabender BB-020

Features:

• Full Cut

• Cut Crease

• Auto Perforate Deepness

• Auto Bridge Height & Width

• Auto-Broach Deepness

• Auto-Broach (optional)

• Auto-Nick (optional)

• High Rule, Label Rule and Thick Rule

Advantages:

• High Bending Accuracy: Precision ground ballscrew to incorporate with professional die making software to acquire high accuracy demand

• High Balancing Flatness: Integrated more than 20 years of die making experience to achieve high balancing flatness of dies

• Wide Range of Rules Support: Can operate for label rules, normal cutting rules, high rules and thick rules

• New Cutting System: New cutting unit for up to 12 auto selectable tools

• Fast Changing Tools: Fast, easy and convenient way of changing tools for using different types of rules

• Two Ways of Cutting: Two-segment cutting function and full-cut function for maintaining length accuracy during bending as well as cutting efficiency

• Side Broaching (Unique Feature):

- Reducing traditional work for manual side broaching on grinding machine

- Combined "V" and "Flat" shapes broaching for joints using tiny lipper

- Joints with broaching suitable for cigarette packaging dies

• Broaching: Broach on sharp angles and tiny arcs of R0.1, R0.2, R0.3 and R0.5mm

• Nicking: 4 different nick widths and auto selection by software

• Perforation: Auto perforation with auto deepness control

• Bridging: Auto adjustable height between 5 and 20mm, three bridge widths available and auto selection by software

Technical Specifications:

• Supported rule height: 7 – 60mm (0.45 – 1.07mm Thick); 12 – 32mm (0.45 – 1.42mm Thick)

• Broaching*: “V” shape & Flat shape, Auto depth adjustment★

• Bridging*: 5 – 20mm Auto Height Adjustment★

• Perforation & Cut-Crease*: Minimum 1mm Width, Maximum 5mm Depth★

• Nicking*: 4 discs auto changer, 0.3 – 0.6mm width★

• Dimensions: Main body L290 x W85 x H170 cm; Standard Cassette Holder L90 x W90 x H120 cm

• Weight: Main body 800kg; Standard Cassette Holder 100kg

• Power: 230VAC Single Phase 3kW

• Air Compressor requirement: 0.6 – 0.8MPa, 8mm conduit diameter

• Cutting tool:Max 12 tools installed

★ Can be customized according to customer specification